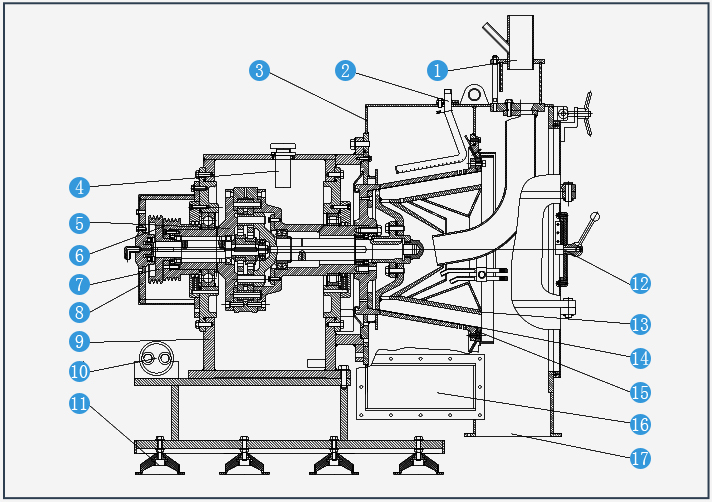

Product Introduction

Product Introduction

Corrosion Resistance

Corrosion Resistance

Main parts as the drum and the screw can be made of corrosion-resistant stainless steel or titanium alloy.

Special Filter Screen

Special Filter Screen

Special filter mesh, with its thickness reaching 0.5mm, holds a longer life expectancy.

Drum Speed

Drum Speed

Stepless speed regulation of drum speed.

Spiral Differential Speed

Spiral Differential Speed

Spiral differential speed is adjustable: stepless or stepless speed regulation.

Circulating Lubrication

Circulating Lubrication

Simple and reliable circulation lubrication method, including pressure regulation, oil filtration and water cooling system.

Safety Protection

Safety Protection

Speed detection, over-vibration protection, motor overload and overheat protection, spiral zero differential protection.

Hydraulic Differential

Hydraulic Differential

For high viscosity materials, a hydraulic differencial can be used to keep the machine stable and reliable.

Equipment Improvement

Equipment Improvement

The improvement of Blovebird's special equipment for extracting salt from waste liquid of ammonium sulfate, ammonium chloride, ammonium thiocyanate and sodium chloride.

The Feeding Pipe Device

The Feeding Pipe Device

The feeding pipe device is improved, the distribution is more uniform, and the equipment operation is more stable.

Lubrication System

Lubrication System

The lubrication system is improved, the lubrication is more adequate and reasonable, and the service life of the bearing is increased.

| Model |

Drum Diameter (mm) |

Drum Speed (r/min) |

Separation Factor |

Feeding (m³/h) |

Power of Motor (kw) |

Weight (kg) |

Overall Dimension (mm) |

| LWL200 | 200 | 4000 | 1790 | 0.5-1.5 | 3 | 550 | 1120X1020X800 |

| LWL250 | 250 | 3500 | 1714 | 1.0-3.5 | 4 | 600 | 1120X1050X850 |

| LWL350 | 350 | 2900 | 1647 | 3.0-7 | 11 | 1200 | 1300X1200X1200 |

| LWL450 | 450 | 2600 | 1702 | 5.0-15 | 22 | 1800 | 1800X1500X1300 |

| LWL530 | 530 | 2200 | 1435 | 8.0-25 | 30 | 2600 | 2000X1700X1600 |

| LWL630 | 630 | 1850 | 1206 | 10-35 | 37 | 2800 | 2000X1700X1650 |

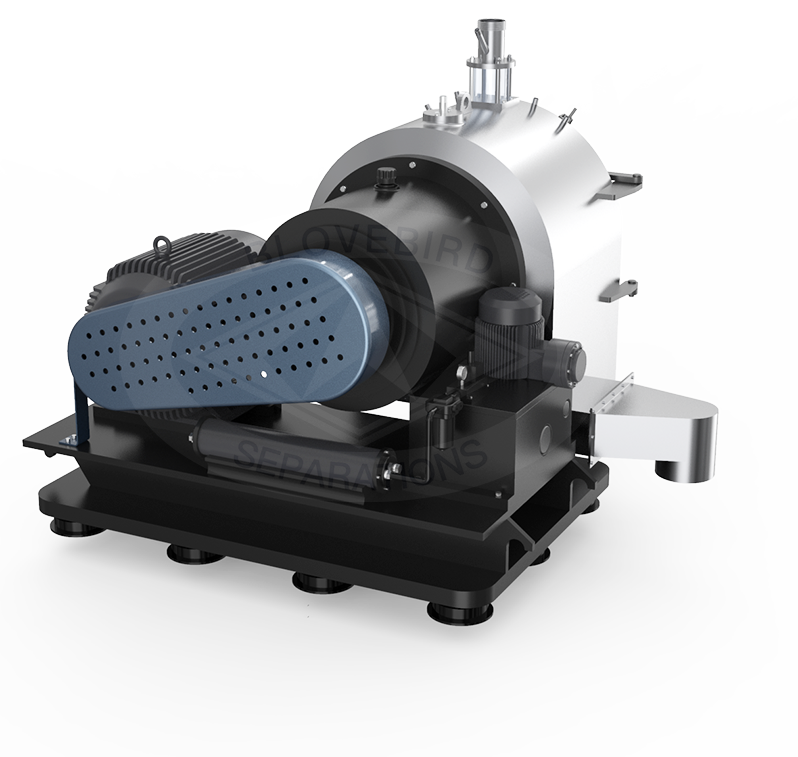

Special Equipment Improvement

Special Equipment Improvement

Horizontal spiral screen centrifuges have been widely used in industries such as chemicals, food, salt, mining, pharmaceutical,etc. However, due to its separation principle and structural characteristics, it is more targeted to materials. Material analysis and corresponding experiments should be carried out during the selection to test out its applicability and separation performance.

It is mainly suitable for material particles with a larger particle size and no strict requirements for particle damage, such as fibers, plastic particles, and various crystals.

Centrifuge Advantage

Centrifuge Advantage

(1) Safety:

1.Over vibration protection

2.Motor overload filter protection

3.Flameproof protection

4.Equipped with speed detection

(2) Protection of Environment:

1.Low energy consumption

2.High airtightness

3.Variable frequency control stepless speed regulation

4.Low vibration and low noise

(3) Efficiency:

1.Continuous work and large processing capacity

2.Easy maintenance and low failure rate

3.Large pushing moment, no material blockage

4.Lower solid phase moisture content

(4) Wide Applicability:

1.Material: 304 ,321, 316L, Titanium alloy, Hastelloy and etc.

2.Configuration: Various differential systems, Various filter media, Various feeding methods, Various lubrication methods

(5) High Degree of Automation:

1.Frequency conversion and PLC control

2.Adaptive compensation for hydraulic differential system

| Adipic Acid | Ammonium Thiosulphate | Naphthenic Sulfonic Acid Ester | Date Stones | Salt Cake |

| Ion Exchange Resin | Sodium Nitre | Polystyrene Alcohol | Arsenic Triazole | Sodium Chloride |

| Sodium Perborate | Sodium Thiosulphate | Ah-salt | Anth Racene | Nylon Chips |

| Copper Sulphate | Greaves | Iron Sulphate Hepta Hydrate | Sodium Phosphate | Potash |

| Rock Salt | Citric Acid | Tarterci Acid | Aminoacetic Acid | Sodium Chlorate |

| Oxalic Acid | Crystal Soda | Gun Powder | Aspirin | Sodium Sulphate |

| Potash Alum | Regenerated Rubber | Lactose | Polymethacrylate | Tin Sulphate |

| Ammonium Persulphate | Sodium Formate | Sodium Sulphite | Dinitro Methylarlin | Gypsum |

| Bisphenol | Polysyrene | Potash Solvent Residue | Silver Nitrate | Manganese Sulphate |

| Sodium Tetraborate | Trisodium | Ammonium Phosphate | Sodium Gluconate | Two Nirto Methylaniline |

| Extraction From Methanol | Urotropin | Borax | Disodium Phosphate | Ammonium Sulphate |

| Methyl Cellulose | Potassium Lore | Potassium Bica Rbonate | Ammonium Sulphate | Sodium Metaborate |

| Potassium Chloride | Zinc Sulphate | Hops From Dichlorc Methare | Calcium Formiate | Polyvinyl Chloride |

| Potassium Bichromate | Monosod lumphasphate | Potassium Sulphate | Potassium Pensuphate | Sodium Ca Rbonate |

| Sodium Nitrate | Polyethylene | Fungal Mycel |

30 Year Brand

Contact Us