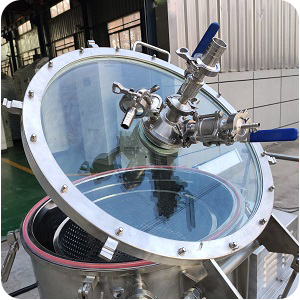

Introduction of Typical Case Plant Extraction Centrifuge EEC30

Separation materials: Plant dry material

Process Description:

The operator fills the filter bag with crushed plant material and puts it in the machine. Then, add alcohol until the plant material is submerged, and set the program to rotate in both directions to fully extract the effective ingredients in the plant. Open the bottom valve to release the extract, and the plant material is rotated at high speed to remove the liquid as much as possible. Then the alcohol lotion is further processed.

Technical Features:

1. Low temperature acceptable -50℃ to 50℃

2. Models 15,30 and 50 are fully transparent explosion-proof glass clamshell structure for clear viewing of the conditions inside the equipment.

3. Automatic extraction process, the program can set the drum positive and negative rotation speed, time and cycle times, and can switch manual control. Dehydration speed and time can be set.

4. Temperature display. Vacuum pressure display.

5. The bottom with leakage indicator port, if there is leakage can be found in time.

6. Zippered filter bag for quick loading and unloading. Designed for single operator.