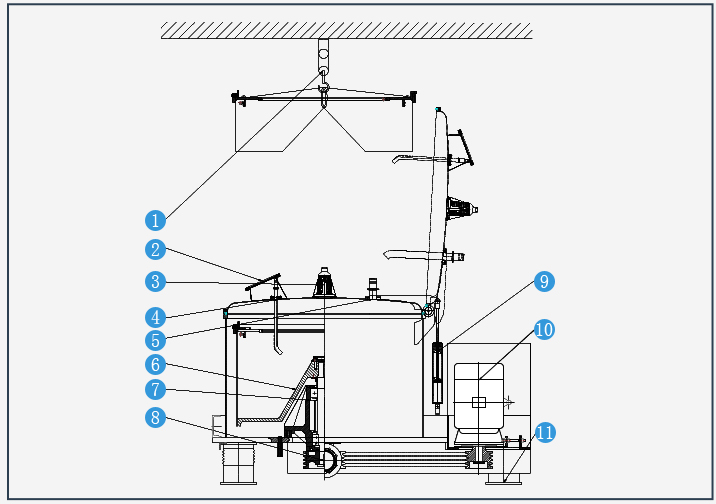

PD Series Introduction

PD Series Introduction

Inverter Start

Inverter Start

Lifting Bag Unloading

Lifting Bag Unloading

Reasonable Structural Design

Reasonable Structural Design

Online Cleaning System

Online Cleaning System

Simple Structure

Simple Structure

Grains

Grains

Nitrogen Protection System

Nitrogen Protection System

Strong Versatility

Strong Versatility

Closed Structure

Closed Structure

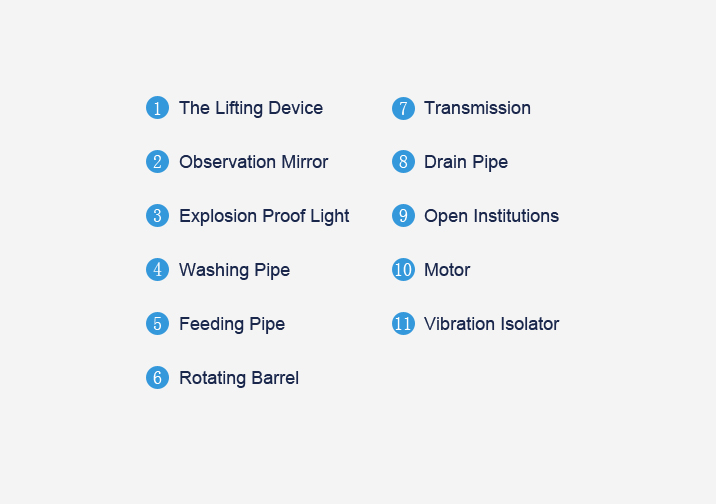

| Model |

Drum Diameter (mm) |

Speed (r/min) |

Separation Factor |

Drum Volume (L) |

Loading Limit (kg) |

Power of Motor (kw) |

Weight (kg) |

Dimension (mm) |

| PD800 | 800 | 1200 | 645 | 100 | 140 | 7.5 | 1500 | 1800X1200X1350 |

| PD1000 | 1000 | 1000 | 650 | 155 | 200 | 11 | 2500 | 2050X1500X1350 |

| PD1250 | 1250 | 970 | 645 | 370 | 500 | 18.5 | 3300 | 2300X1800X1580 |

| PD1500 | 1500 | 870 | 605 | 600 | 800 | 22 | 5500 | 2600X2200X1850 |

| PD1600 | 1600 | 870 | 647 | 800 | 1000 | 37 | 7500 | 3000X2200X1980 |

| PD1800 | 1800 | 720 | 522 | 910 | 1200 | 45 | 10000 | 3200X2550X2150 |

30 Year Brand

Contact Us