Product Introduction

Product Introduction

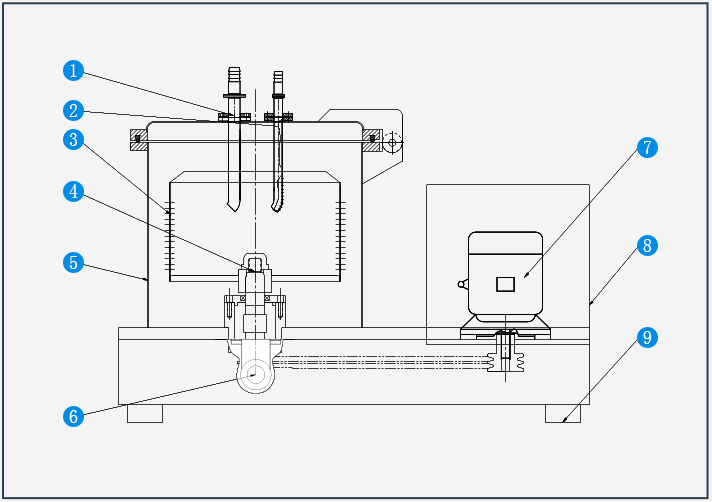

YGD series is a closed structure. The machine adopts a flat plate with a large open cover, and the flip cover is provided with a feeding tube, a washing tube, and a viewing mirror, etc. On-line feeding can be realized (if there is a reaction kettle, it can be directly connected to the centrifuge). The machine runs more smoothly and prettier.It is suitable for the environment with strong smell and need closed operation. The whole machine is stainless steel.

The machine is composed of casing, drum, base, shock absorbing pad, transmission parts, etc. The drum operation is driven by the motor wheel through the triangular belt to drive the passive wheel operation. For the medium with high solid content, the medium with high liquid content is started before feeding (YGD and YGT series can realize on-line feeding and washing functions). The material is uniformly fitted to the drum wall through the centrifugal field The liquid phase is discharged through the filter screen through the drum filter hole, while the solid phase is retained in the drum. When the separation requirements are met, the power supply is cut off (energy consumption braking or braking device makes the drum stop operation), and the material is automatically stopped and discharged from the upper part manually.

Material Selection

Material Selection

Optional SUS304, SUS316L, titanium and plastic lining, etc.

GMP Comliance

GMP Comliance

Designed specifically for laboratories, in line with GMP requirements, high speed, compact and lightweight.

Explosion Proof Motor

Explosion Proof Motor

Use explosion-proof motor.

Meet Quality System Standards

Meet Quality System Standards

Meet the standard of JB/T10769.2-2007 "Technical Conditions of Three-foot and Flat Centrifuge" and GB/T19001-2000idt ISO9001-2000 quality system standard.

Frequency Control

Frequency Control

The motor can be adjusted by frequency conversion, and the feeding, washing and separation speed of the centrifuge can be adjusted randomly.

Reliable Braking Performance

Reliable Braking Performance

The centrifuge adopts the dynamic braking mode of braking unit and braking resistor, and the braking performance is reliable.

Flap Structure

Flap Structure

It adopts a flip-lid structure, each centrifuge is equipped with a spring opening system and 3 quick-action locking buckles, which is light and dexterous, safe and reliable; it is convenient and quick to close the lid and has good sealing.

Feed Pipe Feed

Feed Pipe Feed

Adopting the feeding pipe method to feed materials, the cloth is evenly distributed, and the whole machine runs smoothly.

| Model |

Drum Diameter (mm) |

Speed (r/min) |

Separation Factor |

Working Volume (L) |

Load Limited (kg) |

|

|

Power of Motor(kw) |

Weight (kg) |

Dimension (mm) |

| YGD200 | 200 | 3000 | 1007 | 2 | 3 |

|

0.55 | 75 | 600X360X350 | |

| YGD300 | 300 | 2800 | 1316 | 10 | 12 | 1.1 | 120 | 850X500X500 | ||

| YGD450 | 450 | 1900 | 910 | 20 | 30 |

|

1.5 | 280 | 1000X700X650 |

30 Year Brand

Contact Us